AM-EX Engineering, Fabrication, Field Services

Our Services

Engineering

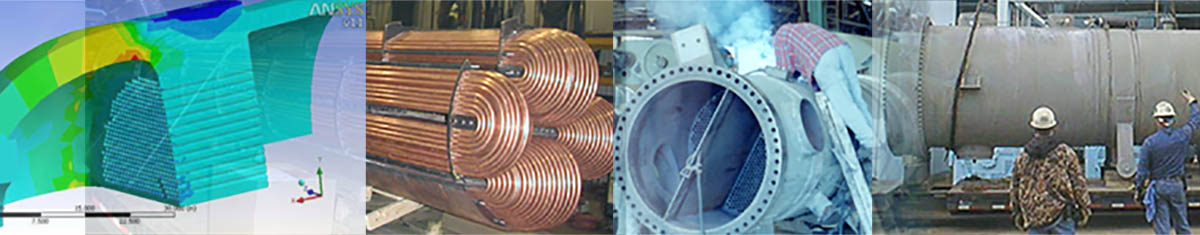

Design engineering is a core competency of American Exchanger Services, Inc. With specialty programs such as in-house Finite Element Analysis, Thermal Rating, and custom proprietary design software, our engineers are well-equipped to develop the most efficient designs for any heat transfer equipment. Exceeding challenging design requirements, our skilled design engineering provides savings with improved equipment reliability.

AM-EX engineers are heat transfer specialists with decades of experience in the field. In order to achieve the most efficient designs, AM-EX engineers developed proprietary feedwater heater and condenser design software which is used in-house along with Thermal Rating and Finite Element Analysis programs.

As leaders in the power generation industry, AM-EX Engineers have published numerous technical papers for ASME and EPRI covering topics such as advanced feedwater heater designs, solving flow induced vibration problem in feedwater heaters, and tube repair using explosive welding.

Manufacturing

All of AM-EX’s equipment is designed to meet or exceed industry standards such as TEMA, HEI, or API 660/661.

AM-EX is ASME Certified Section VIII-1 for Heat Exchangers, Condensers, and Feedwater Heaters holding the “U” Stamp for fabrication, the “R” Stamp for repairs, and the “PP” Stamp for pressure piping. AM-EX is also a National Board Certified Code Shop. AM-EX is certified by ASME to build and stamp vessels according to section VIII. AM-EX is also certified by the NBIC for repairs and alterations. AM-EX was recently awarded as a Manufacturer of the Year for the state of Wisconsin.

AM-EX is a proud member of the Heat Exchanger Institute HEI. AM-EX engineers are recognized as leaders in the field –active in several of the ASME's Power committies, and contributing to many Electrical Power Research Institue EPRI events.

Field Service

American Exchanger Services, Inc. employs dedicated and experienced field technicians. AM-EX technicians provide retubing services for feedwater heaters and condensers, emergency onsite repairs, and diagnostic engineering services. Service equipment is developed in-house and used in the field by our technicians.

Field services performed include:

AM-EX technicians are experienced working in environments including power generation, process, pulp and paper, renewable energy, and nuclear plants throughout the United States as well as internationally. For time-critical repairs, AM-EX is a global provider of 24-hour emergency service.

HERF

High Energy Rate FabricationThe use of High Energy Rate Fabrication (HERF) allows design engineers a level of flexibility in design unattainable by other forming technologies. HERF provides minimal change in material properties, reduced yield strength, and greater complexity.

American Exchanger Services is uniquely equipped and experienced to perform projects involving HERF. For this reason, Scientists from the University of Wisconsin Madison came to AM-EX with a drawing of a new concept in fusion reactor design. This design was a helically symmetric stellerator, which required a highly irregular structure for the vacuum chamber. This design greatly simplifies the operation of the plasma while greatly increasing the fabrication complexity of the reactor. AM-EX was able to work with the scientists to explosively form this extreme shape to very tight tolerances. With operating temperatures in excess of 8 million ºF, this was truly an amazing project for American Exchanger Services to be involved in.

Explosive welding allows for the greatest possible level of tubejoint integrity. It allows the joining of almost any combination of metals and alloys for tubes and tubesheets. The technology involves the impacting of the tube into the tubehole at such high energy rates that the atoms share their electrons across the interface, thus bonding the materials.